Accessories for test weights play a crucial role in maintaining the accuracy and integrity of the test weights over time. Here’s how they contribute to this:

Proper Handling:Tweezers and Gloves: Accessories such as non-magnetic tweezers, weight lifters, and lint-free gloves are designed to handle test weights without direct contact. This prevents contamination from oils, dirt, or moisture from hands, which can affect the weight's mass and surface integrity.Weight Lifters: Ergonomically designed lifters ensure safe handling of heavier weights, reducing the risk of accidental drops or impacts that could alter the weight’s calibration.

Protection from Environmental Contaminants:Storage Cases and Boxes: Custom-designed cases or boxes with individual compartments and padding protect test weights from dust, moisture, and temperature fluctuations, which could otherwise lead to oxidation, corrosion, or changes in weight.Anti-Static Covers and Bags: Protect weights from static electricity and airborne particles, maintaining their surface quality and ensuring precise measurements.

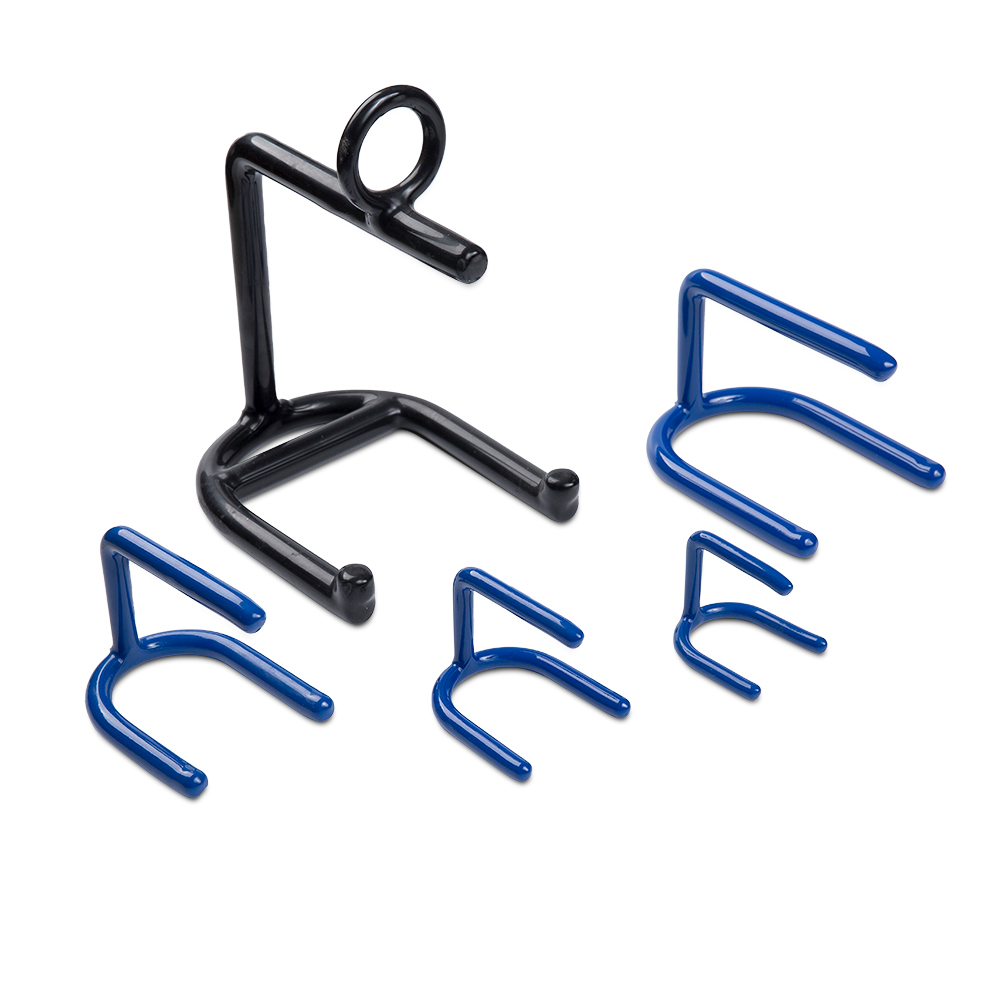

Prevention of Physical Damage:Protective Covers and Trays: Accessories like soft-lined covers and trays prevent scratching, denting, or chipping of weights when they are not in use, ensuring their mass remains unchanged.Shock-Absorbing Bases: For heavier weights, shock-absorbing bases can be used to cushion impacts during handling, reducing the risk of damage that could compromise their calibration.

Cleaning and Maintenance Tools:Soft Brushes and Cleaning Cloths: Specially designed brushes and lint-free cloths help in removing dust and debris without causing scratches or abrasion. Regular cleaning with these tools prevents the accumulation of particles that could affect weight accuracy.Cleaning Solutions: Some accessories include approved cleaning solutions that do not react with the weight material but effectively remove residues that could alter the weight's properties.

Calibration and Adjustment Aids:Calibration Jigs and Adjustment Tools: These accessories help in fine-tuning and adjusting weights when needed, ensuring they remain within their designated tolerance levels. Regular calibration checks with these tools help identify any drift in accuracy and correct it immediately.Digital Calibration Tools: Modern accessories may include digital tools that help in monitoring the calibration status and logging results, enabling timely maintenance and recalibration.

Minimizing Human Error:Guides and Indicators: Some accessories come with guides, labels, or visual indicators that help users correctly place and use test weights, minimizing the chances of improper handling or placement that could affect measurements.Alignment and Centering Tools: Accessories designed to ensure proper alignment and centering of test weights on scales help in achieving consistent readings, maintaining accuracy over repeated uses.

Compliance with Standards:Certified Accessories: Accessories that meet international standards (e.g., OIML, NIST) are designed to maintain the conditions needed for high-precision weights. Using these certified accessories ensures that test weights are handled, stored, and maintained according to strict guidelines that preserve their integrity.

Streamlining Processes for Consistency:Organizational Tools: Accessories such as racks, trays, and labels help organize weights systematically, reducing handling time and potential errors during calibration routines. Consistent practices help maintain weight accuracy over time.

By ensuring safe handling, protecting against environmental factors, providing proper cleaning, aiding in calibration, and minimizing human error, accessories for test weights play a vital role in preserving the accuracy and integrity of the weights over their lifespan. Regular use of the right accessories as part of a well-defined maintenance protocol is essential for any setting where precision calibration is critical.

English

English