Laboratory Calibration Weights require a series of careful measures to ensure accuracy and extend their service life, especially in terms of maintenance and storage. Here are detailed recommendations for maintenance and storage:

Clean regularly according to the frequency of use and environmental conditions. It is recommended to perform a comprehensive cleaning once a month, and frequently used weights should be cleaned more frequently. Use a soft, lint-free cloth or a special cleaning cloth, and avoid using abrasive or chemical cleaners to prevent damage to the surface of the weight. Gently wipe the surface of the weight, paying special attention to removing grease, dust and other contaminants. For stainless steel weights, wash with warm water and ensure that they are completely dry before storing.

Check the appearance of the weight regularly to see if there are scratches, dents or deformations. These damages may affect the measurement accuracy. After a period of use, especially in more demanding environments, recalibration should be performed. Regular calibration ensures that the weight remains within the standard range, and can be sent to a professional institution for testing if necessary.

For metal weights, it is recommended to apply anti-rust oil or wax regularly to prevent oxidation and corrosion, especially in humid environments. Make sure the weight is completely dry before storage, and avoid storing in humid environments to reduce the possibility of rust.

Keep detailed maintenance records, including frequency of use, cleaning date, calibration and any abnormalities found, to facilitate subsequent management and tracking. If a weight needs to be replaced due to wear or damage, record its replacement so that you have a comprehensive understanding of the use of the entire weight series.

Choose an environment with a temperature of around 20°C and a humidity of between 40%-60% to store weights to avoid the effects of extreme temperature and humidity on weight performance. The storage area should be away from direct sunlight to prevent the material from being deformed or degraded due to heat.

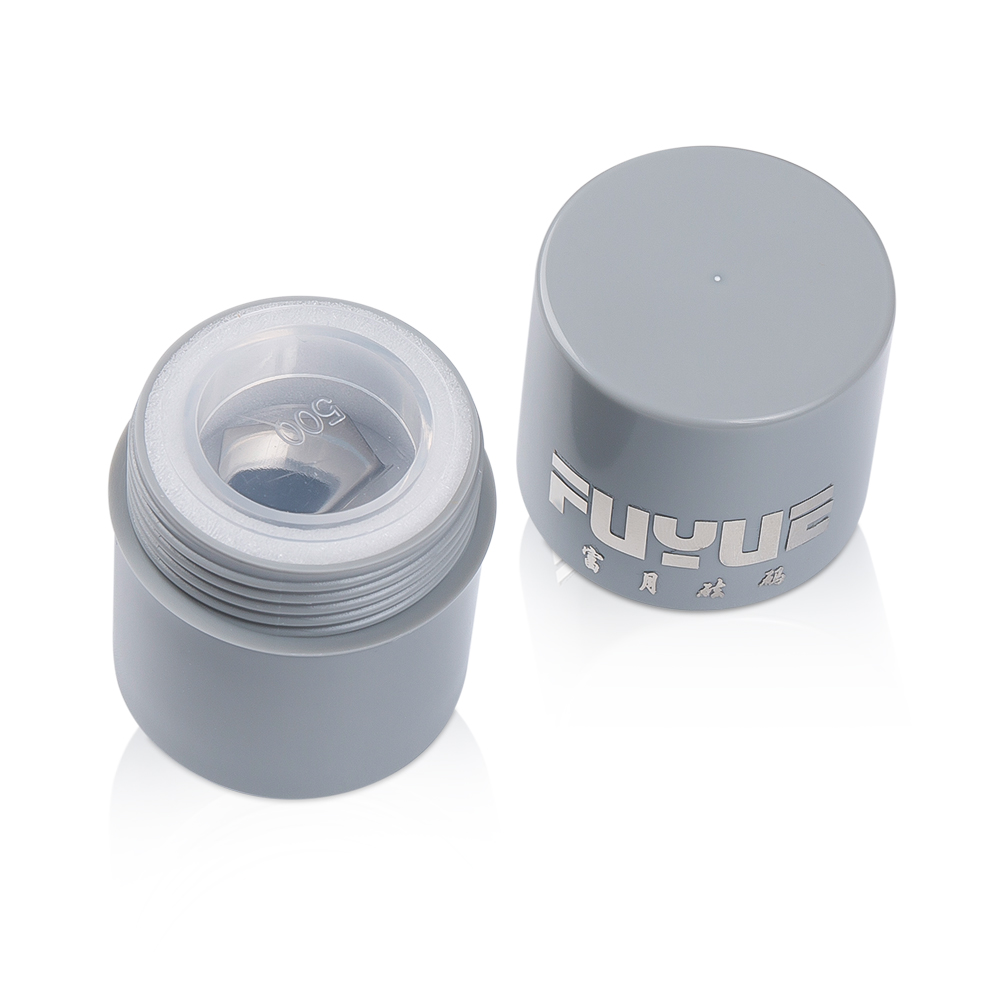

Use a dedicated dust cover or sealed storage box to prevent dust and other contaminants from adhering to the surface of the weight. Place a desiccant in the storage environment to maintain a low humidity environment to prevent moisture from affecting the performance of the weight.

Weights should be stored in a dedicated storage rack or box to avoid direct contact with other items to prevent scratches or wear. Weights should be placed vertically to avoid stacking and collision to prevent damage.

Labeling and classification Label and classify weights of different weights and precisions to facilitate search and use and reduce the risk of misuse. Classify and store weights by frequency of use or category to make commonly used weights easier to access and optimize workflow.

Regular cleaning, proper storage, environmental control and detailed records can not only extend the life of weights, but also improve laboratory efficiency and the credibility of measurement results. The implementation of these measures will ensure the high standards of laboratory quality control and calibration and promote laboratory management to a higher level of professionalism.

English

English