Routine maintenance of Accessory for Test Weights is essential to ensure its normal operation, extend its service life, and maintain measurement accuracy. The following are specific daily maintenance requirements and recommendations:

Cleaning and Sanitation

Regularly clean the surface :

Use a soft cloth or brush to remove dust, dirt and other impurities on the surface of the accessory to prevent these substances from affecting the function of the accessory or causing corrosion.

Avoid contact with chemicals :

If the accessory is exposed to a chemical environment (such as acid and alkali solutions), it should be rinsed with clean water and wiped dry in time to prevent corrosion or damage.

Lubrication Management

Check the lubrication status of moving parts :

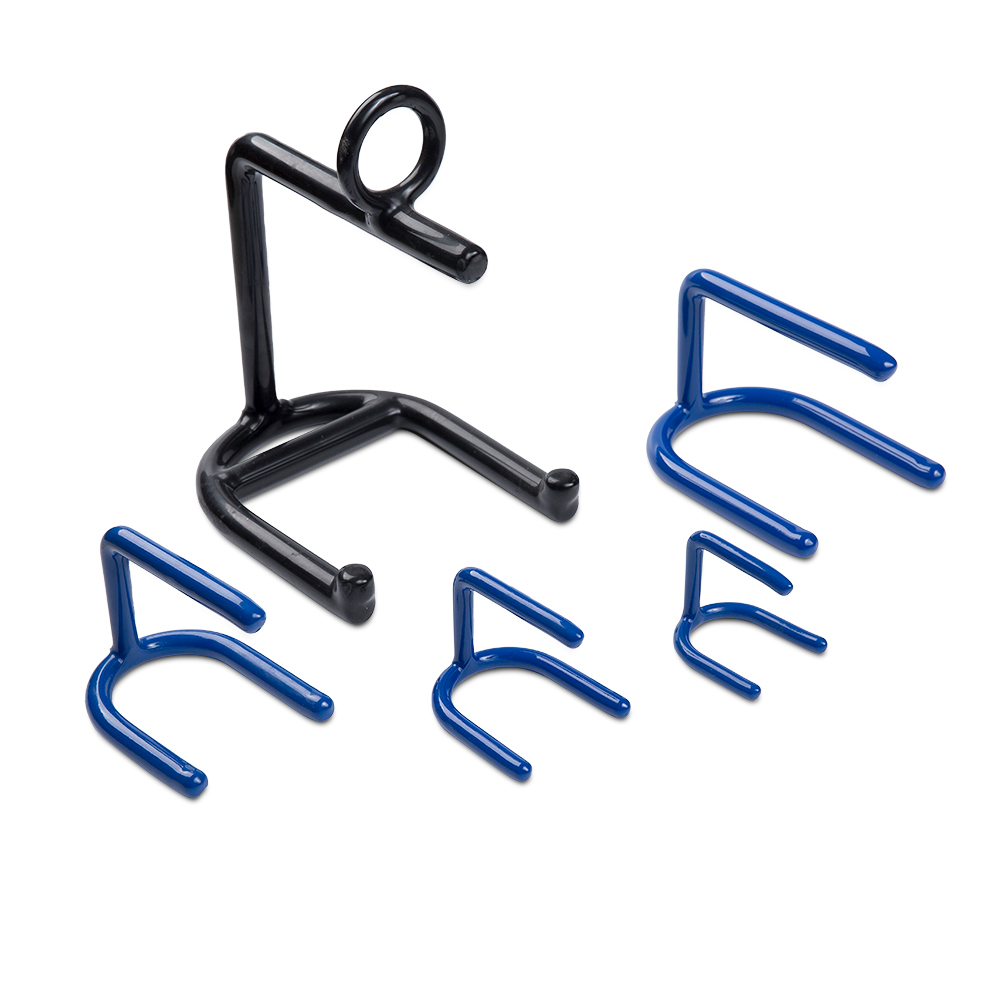

For accessories that need to be moved or rotated frequently (such as clamps, brackets, etc.), the status of the lubricant should be checked regularly to ensure that it is fully lubricated and not dry.

Choose the right lubricant :

Select the appropriate type of lubricant (such as high-temperature grease, anti-rust oil, etc.) according to the working conditions, and use it strictly in accordance with the manufacturer's recommended specifications.

Set the lubrication cycle :

According to the frequency of use and environmental conditions, establish a reasonable lubrication cycle. For example, under high load or high temperature conditions, the lubricant may need to be replenished more frequently.

Fastener inspection

Check the tightness of bolts and nuts:

Regularly check whether the bolts and nuts that fix the accessories are loose. Looseness may cause the accessories to shift or fall off, affecting the stability of the system.

Use appropriate torque value:

When re-tightening, follow the torque value recommended by the manufacturer to avoid damage caused by over-tightening or over-loosening.

Wear and damage detection

Observe appearance changes:

Regularly check the appearance of accessories for obvious wear, cracks or deformation. If problems are found, they should be replaced in time.

Function test:

Before each use, perform a simple functional test on the accessories to ensure that they can work properly. For example, check whether the clamp is firm and the tray is stable.

Anti-corrosion measures

Rust-proof treatment:

For metal accessories, anti-rust oil or anti-rust coating can be applied regularly, especially when used in humid or salt spray environments.

Storage environment control:

Store accessories in a dry and well-ventilated place to avoid long-term exposure to moisture or corrosive gases.

Temperature and humidity monitoring

Monitor the working environment:

Ensure that the accessories are used within the appropriate temperature and humidity range. Extreme environments may accelerate material aging or cause performance degradation.

Take cooling or insulation measures:

If the accessories need to work in high or low temperature environments, consider adding cooling devices or insulation layers to protect their performance.

Regular calibration and inspection

Calibration frequency:

Develop a regular calibration plan based on the frequency and importance of use. For example, perform a comprehensive inspection and calibration of key accessories once a year or every six months.

Record maintenance data:

Establish a maintenance file to record the results and maintenance content of each inspection in order to analyze trends and predict potential problems.

Spare parts management

Prepare necessary spare parts:

Stock spare parts for key accessories (such as fixtures, pallets, etc.) in advance to cope with sudden failures and reduce downtime.

Update spare parts inventory regularly:

Ensure that the quality and quantity of spare parts meet actual needs to avoid delays in maintenance due to out-of-stock.

Professional training and technical support

Operator training:

Ensure that maintenance personnel are familiar with the structure, function and maintenance requirements of accessories and can correctly perform daily maintenance tasks.

Seek professional technical support: If you encounter complex problems, you should contact the manufacturer or professional technicians in time to obtain technical support and solutions. Regular cleaning, lubrication, fastener inspection and anti-corrosion treatment of Accessory for Test Weights can effectively prevent failures and extend the service life of accessories and the overall system. At the same time, establishing a complete maintenance plan and spare parts management system will help improve the reliability and operating efficiency of the equipment. These measures can not only ensure measurement accuracy, but also reduce maintenance costs and improve work efficiency.

English

English